At FSA Systems we have a wealth of knowledge and experience gained over decades of working in the industry – in the manufacturing, supply, and installation of waterproofing membranes in various countries across Europe. We supply only the highest quality modified bitumen waterproofing membranes, produced in a state-of-the-art facility in Italy under the exacting standards of ISO 9001, with a variety of systems and application methods available to suit all types of flat roofs and structural decks in either the new construction or renovation markets.

Our SureBond systems include vapour control layers, underlays, cap sheets, and a variety of complementary ancillary products. All membranes comprise either APP, SBS or special self-adhesive compounds. EPDM is also available.

Every cap sheet is available with AR (anti-root) additives for use on Green Roofs. For cap sheets with a mineral surface finish, Olivine granules, which have CO₂ neutralising properties, are also available, as are white granules which provide high reflectivity for Cool Roof projects. Furthermore, the technical characteristics of SureBond membranes are adapted to meet the demands and requirements for any particular country – for example, EN 1109:1999 Determination of flexibility at low temperature; ENV 1187-1 External fire exposure.

For the UK market, certain products are covered by BBA certificate number 24/7219.

For the Dutch market, certain products are covered by KOMO® certificate number CTG-745/1.

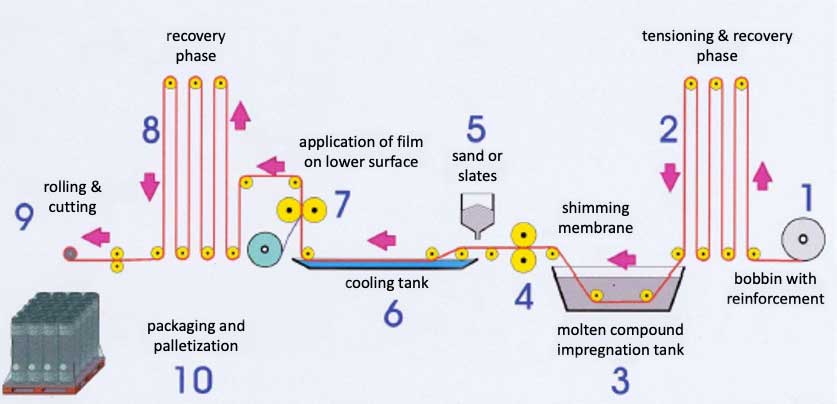

Production of polymer modified bitumen membranes is a highly complex and technical operation. To ensure we meet our customers’ demands and expectations, extensive R&D is undertaken by laboratory technicians at the factory, as well as regular testing of SureBond membranes during the manufacturing process, including but not limited to:

All our membranes partly contain recycled raw materials, such as production waste that is reconditioned and reused instead of being sent to landfills. Furthermore, our membranes do not contain dangerous substances and are 100% recyclable.

All our membranes partly contain recycled raw materials, such as production waste that is reconditioned and reused instead of being sent to landfills. Furthermore, our membranes do not contain dangerous substances and are 100% recyclable.